Hey there, welding newbie (or maybe just welding-curious)! Ever get lost in the alphabet soup of welding processes? MIG, TIG, stick... it's enough to make your head spin faster than a grinder disc! Today, let's tackle two of the biggies: MIG and TIG welding. Think of it as a welding face-off, but without the headgear and (hopefully) fewer sparks flying into your face. Always wear your safety gear, folks! Seriously.

MIG Welding: The Speedy Gonzales of Welding

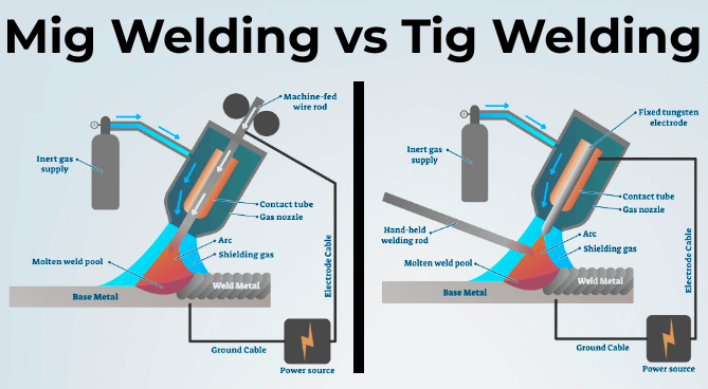

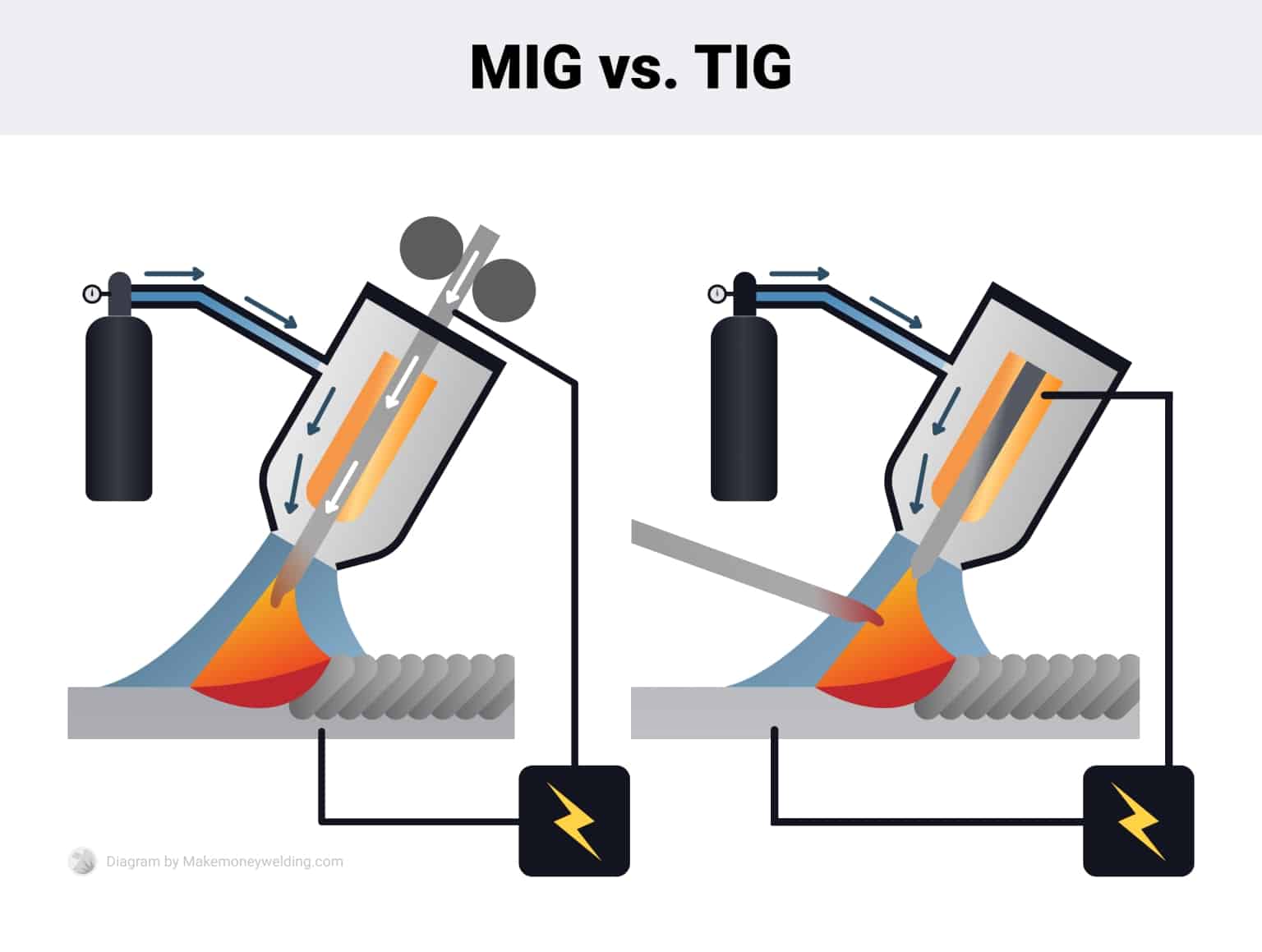

MIG, short for Metal Inert Gas welding (or Gas Metal Arc Welding – GMAW if you're feeling fancy), is often called the "hot glue gun" of the welding world. Okay, maybe that's an exaggeration, but it *is* known for its speed and relative ease of use. Imagine a spool of wire constantly feeding into the weld, all while being shielded by a lovely inert gas (usually argon or a mix of argon and CO2) to keep the weld clean. This automatic wire feed is awesome if you tend to get distracted easily – like, squirrel! – because you don't have to manually feed filler metal.

Think of MIG welding as the go-to for production welding, auto body repair, and DIY projects where speed trumps ultimate finesse. It's great for thicker materials, too! Got a rusty old truck bed to fix? MIG might be your friend. Need to weld up a bunch of garden art gnomes? Well, maybe… but TIG could give you a more artistic finish. We'll get there!

Pros of MIG: Fast, easy to learn (relatively!), good for thicker materials, and versatile. Cons? Can be a bit messy (spatter alert!), not ideal for super thin materials, and the weld appearance isn’t always the prettiest. It's like the comfort food of welding – gets the job done, but maybe isn't gourmet.

TIG Welding: The Artist's Choice

TIG, or Tungsten Inert Gas welding (also known as Gas Tungsten Arc Welding – GTAW – for those keeping score), is like the zen master of welding. It’s all about precision, control, and beautiful welds. Imagine using a foot pedal (or a thumb control on the torch) to precisely control the heat, and then delicately adding filler metal with your other hand. It’s like playing the world's hottest, sparkiest piano.

TIG welding uses a non-consumable tungsten electrode to create the arc, and you manually feed in filler metal (if you need it). This gives you incredible control over the weld puddle and the amount of metal you're adding. This control is why TIG is the champ for welding thin materials like aluminum, stainless steel, and even exotic metals. Need to weld up a titanium exhaust for your race car? TIG is calling your name!

But, with great power comes great responsibility (and a steeper learning curve!). TIG welding requires more skill and practice to master. It's a slower process than MIG, but the results can be stunning. Think of it as the fine art of welding – it takes time, patience, and a steady hand. And maybe a good cup of coffee (or three).

Pros of TIG: Creates beautiful, clean welds, excellent for thin materials and exotic metals, highly precise. Cons? Slower, requires more skill, steeper learning curve, and more expensive equipment. It's like the gourmet meal of welding – worth the effort, but takes some practice!

MIG vs. TIG: The Showdown!

So, which one is better? Well, it depends! It's like asking if a hammer is better than a screwdriver. Both are tools, but they're designed for different jobs. Generally:

- Choose MIG if: You need to weld quickly, are working with thicker materials, and prioritize speed over aesthetics.

- Choose TIG if: You need precision, are working with thin or exotic materials, and want a beautiful, high-quality weld.

And hey, if you're feeling adventurous, why not learn both? The more you know, the better! Think of it as expanding your welding vocabulary.

Here's a little secret: Many welders start with MIG, learn the basics, and then move on to TIG for more specialized work. There's no shame in starting with the "hot glue gun" before moving on to the artistic expression of TIG. We all start somewhere!

So, there you have it! A whirlwind tour of MIG and TIG welding. Hopefully, this has demystified things a bit and you’re now one step closer to becoming a welding wizard. Now go forth and make some sparks fly (safely, of course)! Remember to always wear your PPE, respect the power of the arc, and have fun. Happy welding!