Ever watched a welder at work, mesmerized by the sparks flying and the metal magically fusing together? Welding might seem like arcane wizardry, but the basic idea is pretty straightforward: you're just using heat to join two pieces of metal. But here's where it gets interesting – there are different ways to conjure that heat, and two of the most popular methods are TIG and MIG welding. Knowing the difference can be super useful, whether you're planning a DIY project, commissioning a custom metal piece, or just want to impress your friends with your welding knowledge!

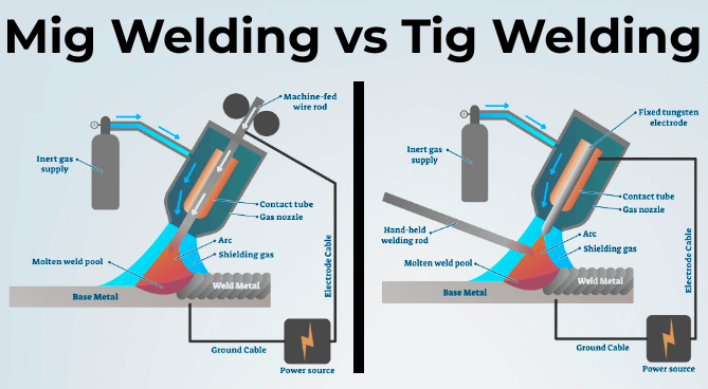

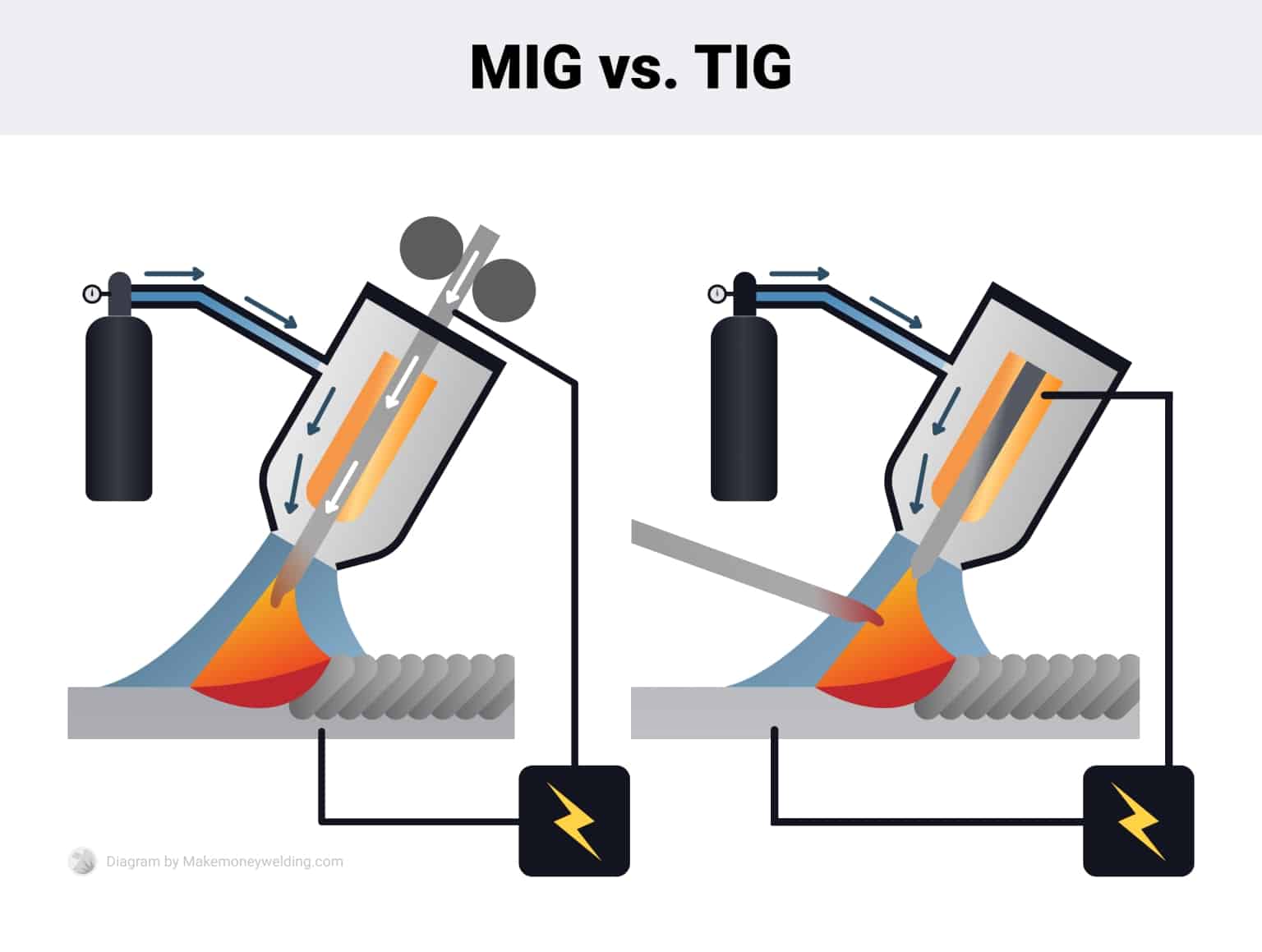

Let's start with MIG welding, which stands for Metal Inert Gas welding. Think of it as the "point-and-shoot" of the welding world. In MIG welding, a wire electrode is continuously fed through a welding gun, melting the metal as it goes. At the same time, an inert gas (like argon or carbon dioxide) shields the weld from the atmosphere, preventing contamination. The purpose of MIG welding is to create a strong, clean weld relatively quickly. Its biggest benefit? Speed and ease of use. It's great for thicker materials and longer welds, making it a favorite in auto body repair and manufacturing. Imagine fixing a dent in your car or assembling a metal frame – MIG is often the go-to choice.

Now, let's move onto TIG welding, or Tungsten Inert Gas welding (sometimes called GTAW – Gas Tungsten Arc Welding). TIG welding is a bit more like playing a musical instrument; it requires a steady hand and a bit more finesse. Instead of a continuously fed wire, TIG uses a non-consumable tungsten electrode to create the arc. You then feed filler metal (if needed) with your other hand. Like MIG, it uses an inert gas to shield the weld. The beauty of TIG is in its precision and control. You can weld thinner materials, like aluminum and stainless steel, with incredible accuracy, and create beautiful, clean welds that require very little cleanup. Think intricate artwork, custom motorcycle frames, or anything that needs a flawless finish – TIG is your artistic welding weapon.

So, what are the key differences? MIG is generally faster and easier to learn, making it ideal for beginners and production environments. TIG is slower and requires more skill, but it offers superior control and weld quality, perfect for delicate work and exotic metals. MIG can handle thicker materials more easily, while TIG excels with thinner gauges. Think of it this way: MIG is like a power drill, great for getting the job done quickly, while TIG is like a scalpel, precise and perfect for detail work.

Ultimately, the best welding method depends on the specific project. If you're tackling a large project that requires speed and strength, MIG welding might be your best bet. But if you need precision, control, and a beautiful finish, TIG welding is the way to go. Now that you know the basics, you can appreciate the artistry and skill that goes into every weld, regardless of the method. And who knows, maybe you'll be inspired to pick up a welding torch yourself!