Alright, let's talk sparks – not the kind that fly when you meet 'the one,' but the kind that bond metal together. We’re diving into the world of welding, specifically the showdown between MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas). Think of it as the Marvel vs. DC of the metalworking universe; both are superheroes, but they have very different powers and appeal to different kinds of artisans.

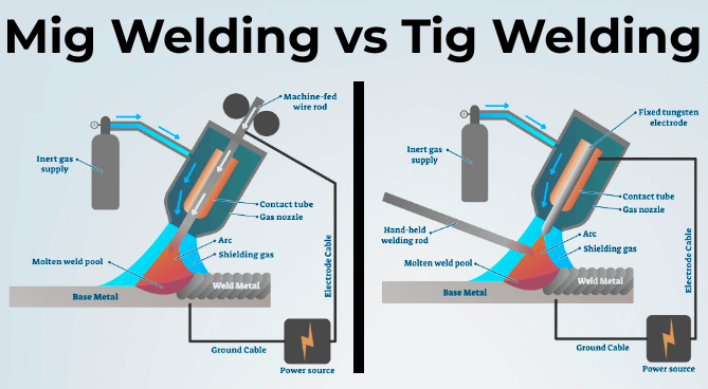

First up, MIG welding, sometimes called GMAW (Gas Metal Arc Welding) – because, you know, acronyms are cool. Imagine it as the point-and-shoot camera of welding. It’s relatively easy to learn, fast, and great for thicker materials. Think of building a fence, repairing a car frame, or even creating industrial structures. It's the workhorse of the welding world.

Practical Tip: When MIG welding, keep your gas nozzle clean! A dirty nozzle can lead to poor gas coverage, which means weaker welds and more spatter. No one likes spatter.

Now, let's talk about TIG welding, also known as GTAW (Gas Tungsten Arc Welding). This is the artisanal bread maker, the craft cocktail mixologist, the one who takes their time and cares about every detail. TIG welding requires a steady hand, finesse, and a deeper understanding of the process. It's like painting with electricity.

Why the extra effort? Because TIG welds are incredibly clean, precise, and strong. It's perfect for thinner materials, exotic metals like titanium or aluminum, and projects where aesthetics matter. Think intricate sculptures, aerospace components, or even high-end bicycle frames. It’s the choice of those who value craftsmanship above all else.

Fun Fact: Did you know that TIG welding was initially developed during World War II to weld magnesium alloys on aircraft? Talk about pressure!

So, What's the Real Difference?

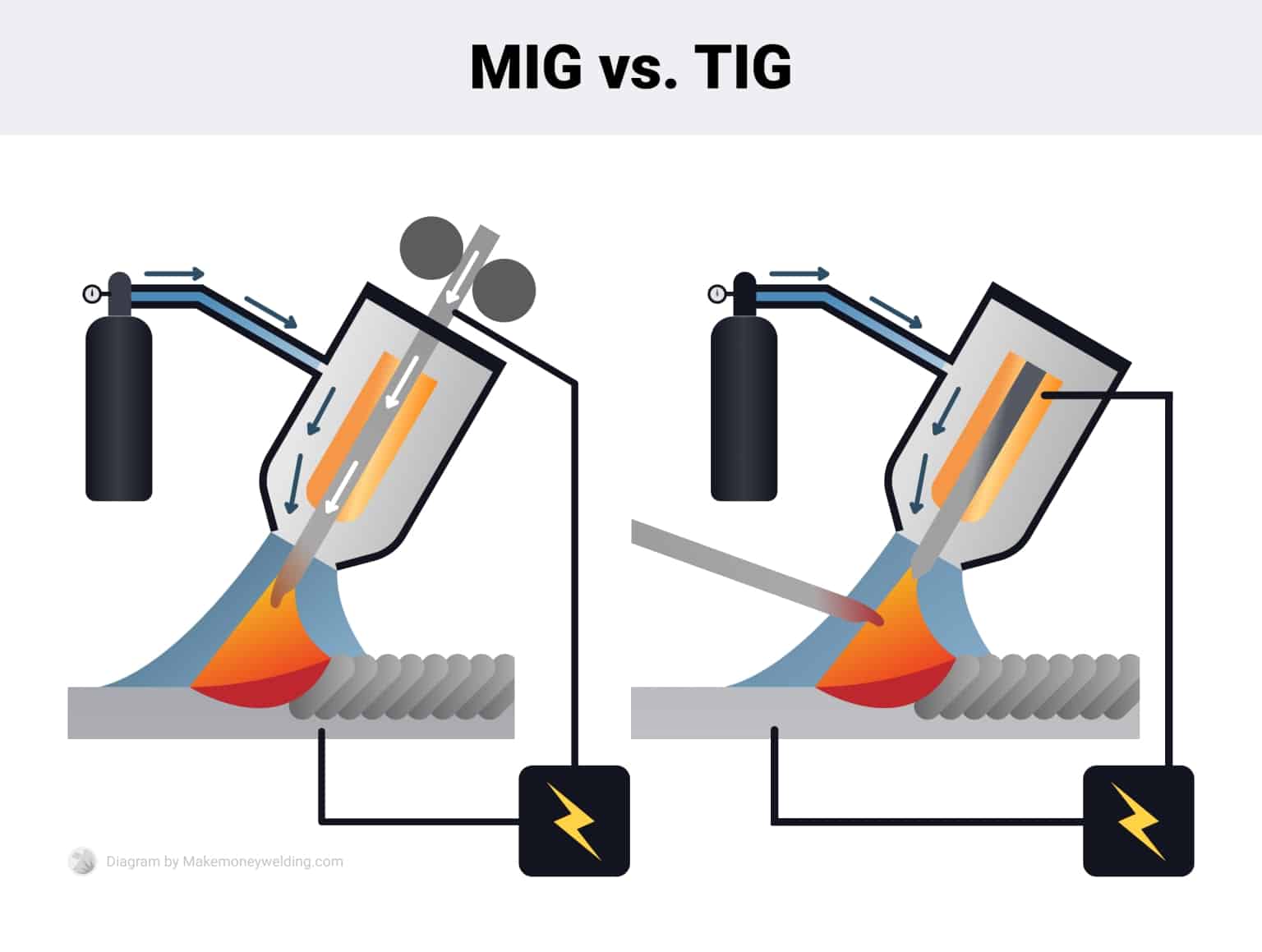

The core difference boils down to a few key things:

- Ease of Use: MIG is generally easier to learn and faster to use. TIG has a steeper learning curve and requires more skill.

- Materials: MIG is good for thicker materials like steel. TIG excels on thinner materials and can handle a wider range of metals, including aluminum, stainless steel, and titanium.

- Cleanliness: TIG welds are cleaner and produce less spatter than MIG welds.

- Control: TIG gives you greater control over the heat input and weld bead, allowing for more precise and aesthetically pleasing welds.

- Speed: MIG is significantly faster than TIG, making it ideal for production welding.

Think of it this way: MIG is like using a power drill – quick and efficient. TIG is like using a scalpel – precise and controlled. Both are valuable tools, but they serve different purposes.

Cultural Reference: Remember that scene in "Flashdance" where Alex Owens welds? While the movie doesn't specify, she's likely using MIG, given the industrial setting and the sparks flying everywhere.

Choosing the Right Process

Deciding which process to use depends on the project, your skill level, and your desired outcome.

If you're a beginner: Start with MIG. It's more forgiving and will allow you to get comfortable with the basics of welding.

If you need to weld thick steel quickly: MIG is your go-to.

If you're working with thin or exotic metals: TIG is the better choice.

If you want clean, precise, and aesthetically pleasing welds: TIG is the way to go.

Practical Tip: Invest in good personal protective equipment (PPE)! Welding helmets, gloves, and proper clothing are essential for safety. Don't be a statistic.

Beyond the Weld: A Daily Life Connection

Welding, in its essence, is about joining things together, creating connections that are stronger than the individual parts. Whether it's the steel beams that hold up a skyscraper or the delicate welds on a piece of art, the principle remains the same.

And isn't that a metaphor for life itself? We're constantly striving to connect with others, to build relationships, and to create something meaningful that lasts. Just like a good weld, these connections require effort, skill, and a little bit of heat. Sometimes things get messy, there's spatter and sparks, but in the end, we hope to create something beautiful and strong.

So, the next time you see a welded structure, remember that it's not just metal that's been joined together. It's a testament to human ingenuity, skill, and the enduring desire to build and connect.