There's something undeniably satisfying about wielding a cutting torch. Maybe it's the controlled power, the hiss of the gas, or the satisfying *sizzle* as you slice through metal. For many, it's a blend of utility and artistry, a practical skill that also allows for creative expression. Whether you're a seasoned fabricator or a weekend warrior tackling a home project, the ability to precisely cut and shape metal opens up a world of possibilities.

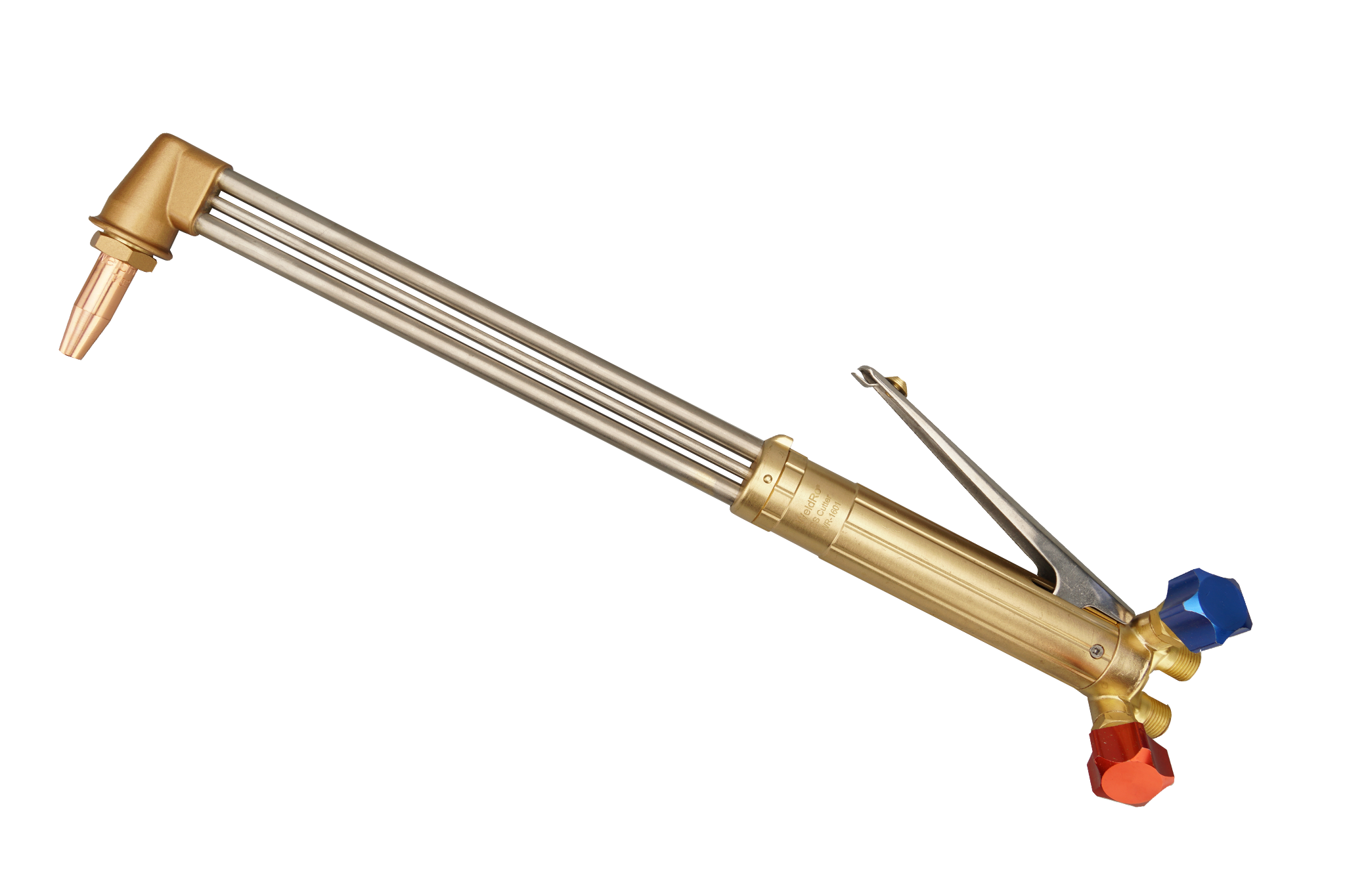

At its core, a cutting torch is a tool that uses a mixture of gases, typically oxygen and acetylene or propane, to generate an intensely hot flame capable of melting and cutting through metal. This might seem like a niche application, but its benefits permeate everyday life in ways you might not realize. Think about it: the construction industry relies heavily on cutting torches for shaping steel beams, demolishing structures, and creating intricate metalwork. Automotive repair shops use them to remove rusted bolts, modify exhaust systems, and repair body damage. Even artists employ cutting torches to sculpt stunning metal creations.

Consider some common examples. Farmers might use a cutting torch to repair agricultural equipment, build fences, or dismantle old machinery. Homeowners might need one for tasks like removing stubborn pipes, fabricating custom brackets, or even creating decorative metal accents for their homes and gardens. And let's not forget the DIY enthusiasts who build everything from custom car parts to unique furniture pieces. The versatility of a cutting torch is truly remarkable.

So, how can you enjoy using a cutting torch more effectively and safely? Here are a few practical tips to keep in mind:

- Prioritize Safety: This is paramount. Always wear appropriate safety gear, including eye protection (welding goggles or a face shield), gloves, and fire-resistant clothing. Ensure proper ventilation to avoid inhaling harmful fumes, and keep a fire extinguisher nearby.

- Choose the Right Torch and Tips: Tractor Supply offers a variety of cutting torches and tips designed for different metal thicknesses and applications. Selecting the appropriate tip will ensure a clean, efficient cut and prevent damage to your equipment. Don't hesitate to ask a store associate for guidance.

- Master the Technique: Practice makes perfect. Start with scrap metal and gradually increase the complexity of your projects. Focus on maintaining a steady hand, consistent travel speed, and the correct flame settings. There are numerous online resources and tutorials that can help you hone your skills.

- Maintain Your Equipment: Regular maintenance is crucial for safety and performance. Check hoses for leaks, clean tips regularly, and inspect all components for wear and tear. A well-maintained cutting torch will last longer and perform more reliably.

- Consider the Material: Different metals require different techniques. Aluminum, for example, conducts heat very quickly and can be more challenging to cut than steel. Research the properties of the metal you're working with and adjust your technique accordingly.

Ultimately, mastering the cutting torch is a journey of continuous learning and refinement. But with the right equipment, proper safety precautions, and a dedication to practice, you can unlock a world of creative and practical possibilities. Head down to Tractor Supply, explore your options, and get ready to experience the satisfaction of shaping metal with the power of a cutting torch!