Okay, so picture this: I was trying to bake cookies for a bake sale last year. Naive me, I thought, "Hey, I'll just double the recipe! More cookies, more profit!" Yeah, right. Suddenly, I needed a bigger bowl (didn't own one), more oven trays (borrowed from a neighbor, awkward!), and it took, like, twice as long, plus clean up… a DISASTER! It made me think – doubling the cookies didn’t just double the ingredients. Everything else seemed to explode too!

Turns out, what happened to me with those disastrous cookies is a real thing in the business world. It's all about how costs change when your production volume changes. It's basically a tango between activity and expenditures. Think of it like this: if you make more stuff, will your costs go up? How much? And will they go up in a predictable way?

The Core Idea: Cost-Volume Relationship

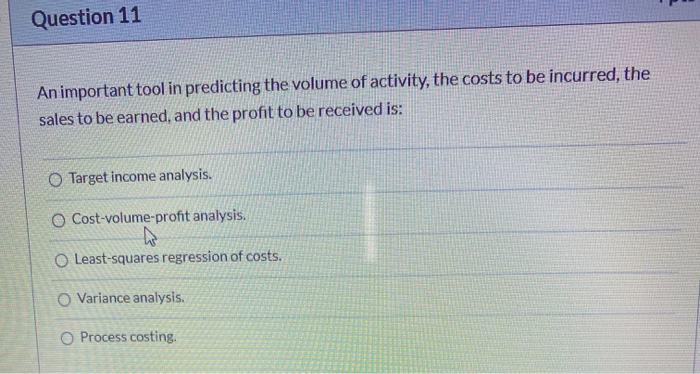

This brings us to the heart of the matter: Cost-Volume Relationship. It's the study of how costs are impacted by the level of activity. That "activity" could be anything - units produced, customers served, hours worked – anything you can *measure* that tells you how busy you are.

Now, costs don't all behave the same way. Some are total drama queens, changing drastically with every minor shift in activity. Others are more like stoic monks, barely budging no matter what you throw at them. And some are… well, let's just say they're complicated.

Types of Costs: The Usual Suspects

Here's where we get into the nitty-gritty. Costs are generally categorized into three main types based on how they react to changes in activity:

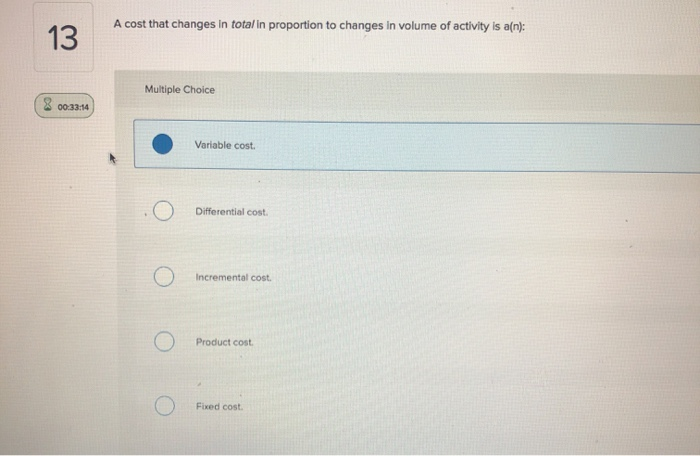

- Variable Costs: These are the *super sensitive* ones. They change directly and in proportion to the level of activity. If you double your output, your variable costs roughly double too. Things like raw materials (flour for those cookies!), direct labor (someone's gotta mix!), and even the electricity to run the machines can be examples.

Think of it like this: More cookies equals more flour used. Makes sense, right?

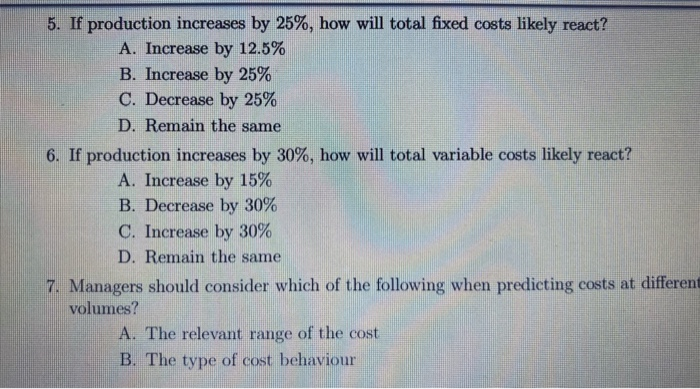

- Fixed Costs: These are the *opposite* of variable costs. They stay relatively constant regardless of the level of activity. Rent on your factory, salaries of your managers, and insurance premiums are usually fixed (at least in the short term).

Whether you bake 10 cookies or 1000, your rent probably stays the same. Unless you need to rent a bigger bakery... then things get complicated. See, I told you!

- Mixed Costs: These are the *complicated* ones. They have a bit of both! They have a fixed component (a base cost you pay no matter what) AND a variable component (that changes with activity). Imagine your phone bill: you have a flat monthly fee PLUS charges for data usage.

Figuring out mixed costs is like untangling Christmas lights. Fun! ...Said no one, ever.

Proportional Changes: Where It Gets Interesting

Let's zero in on the idea of costs changing *in proportion* to volume. This largely applies to variable costs. If your production volume increases by 10%, your variable costs should ideally increase by roughly 10% as well. Of course, the real world is rarely that perfect. There are always factors that can throw things off.

For example, you might get a bulk discount on materials when you buy more. (Yay for bulk cookie ingredient savings!) Or, maybe your production process becomes *more* efficient as you scale up (less wasted dough, faster baking times!). These are called economies of scale, and they can actually cause your variable costs to increase at a slower rate than your activity.

On the flip side, you might run into diseconomies of scale. This is when your costs start increasing faster than your activity. Maybe you need to hire more supervisors as your team grows, and coordination becomes a nightmare. Or maybe your equipment starts breaking down more frequently because it's being used so hard. (Oven burnout = no cookies!)

Why Does This Even Matter?

Understanding how your costs change with volume is *crucial* for making smart business decisions. It helps you:

- Set prices: You need to know how much it *really* costs to produce something before you can decide how much to charge for it.

- Forecast profits: By predicting how your costs will change as your sales increase (or decrease!), you can get a better idea of your future profitability.

- Make operational decisions: Should you invest in new equipment to increase production? Should you outsource some of your processes? Cost-volume analysis can help you answer these questions.

So, next time you're trying to scale up your cookie empire (or any other business venture!), remember my baking mishap and take a good, hard look at your costs. Understanding the relationship between costs and volume can be the difference between a sweet success and a total cookie catastrophe!