Let's face it, there's something incredibly satisfying about fixing things yourself. That feeling of accomplishment when you've resurrected a broken object, or crafted something entirely new, is hard to beat. And for many DIYers, hobbyists, and professionals alike, brazing is a key skill in achieving that satisfaction.

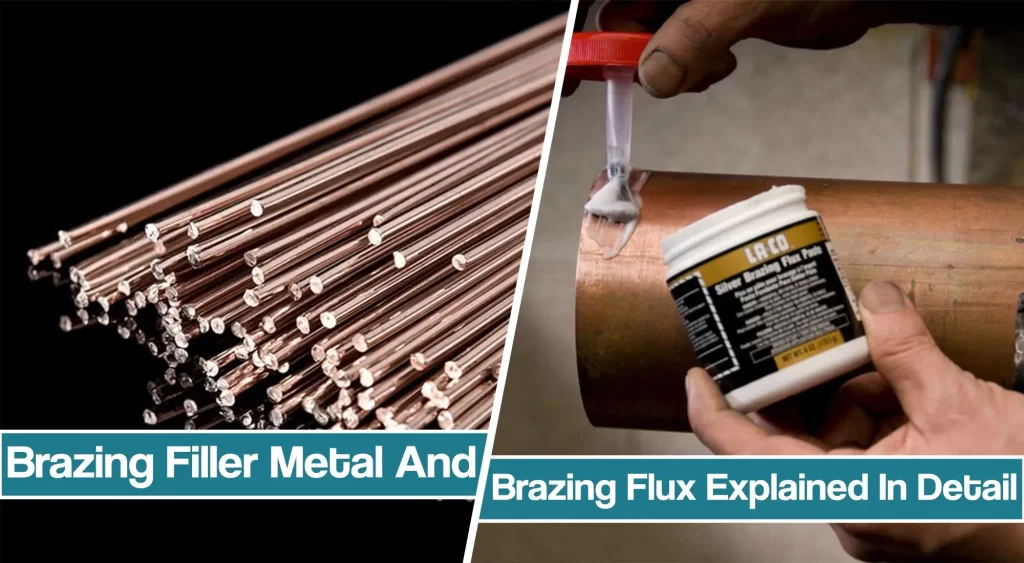

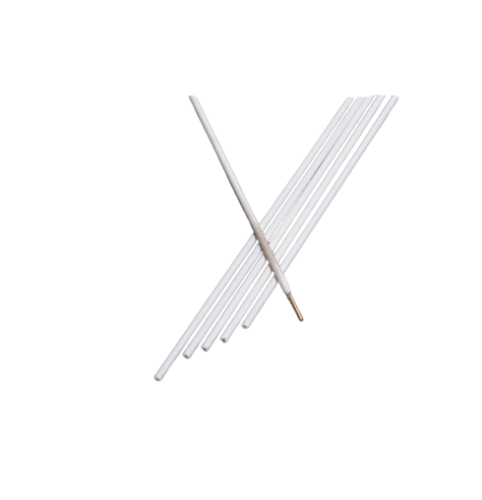

Now, if you're familiar with brazing, you've probably encountered coated brass brazing filler metal. It might sound a bit technical, but its purpose is quite straightforward: to join two metal pieces together with a strong, neat bond. But why coated brass, and why is it so useful?

The benefits are numerous. Coated brass brazing rods, particularly those with a flux coating, offer a significant advantage over traditional, uncoated rods. The coating, typically a flux, does the vital job of cleaning the metal surfaces as they're heated. This is crucial because oxides and other impurities can prevent the brazing filler metal from properly adhering. The flux melts and flows, removing these contaminants and allowing the molten brass to create a strong, metallurgical bond. This translates to joints that are not only strong but also resistant to corrosion.

Think about it: anything from plumbing repairs in your home to automotive work to crafting intricate metal sculptures can rely on the strength and reliability of brazed joints made with coated brass. You might find it in refrigerator coils, air conditioning systems, or even bicycle frames! Its ability to join dissimilar metals, like copper and steel, makes it incredibly versatile.

So, how can you get the most out of your coated brass brazing adventures? Here are a few practical tips:

- Surface Preparation is Key: Even with the flux coating, a quick cleaning of the metal surfaces with sandpaper or a wire brush goes a long way. Remove any heavy rust, grease, or dirt before you start.

- Heat Control is Crucial: Don't overheat the metal! Brazing relies on capillary action, where the molten filler metal is drawn into the joint. If the metal is too hot, the flux will burn off prematurely, and the brass may simply ball up instead of flowing smoothly. Aim for a consistent, even heat.

- Choose the Right Rod: Coated brass brazing rods come in different diameters and with varying flux compositions. Select the appropriate rod size for the thickness of the metal you're joining and the type of metal you're working with. Read the manufacturer's instructions!

- Practice Makes Perfect: Don't be discouraged if your first few attempts aren't perfect. Brazing, like any skill, takes practice. Experiment with different techniques and heat settings to find what works best for you. Use scrap metal to hone your skills.

- Ventilation is Important: Brazing fumes can be harmful, so always work in a well-ventilated area or use a respirator.

With a little knowledge and practice, you can master the art of brazing with coated brass filler metal and unlock a whole new world of DIY possibilities. So grab a torch, some safety glasses, and get ready to create strong, reliable, and beautiful metal joints. You might just surprise yourself with what you can achieve!