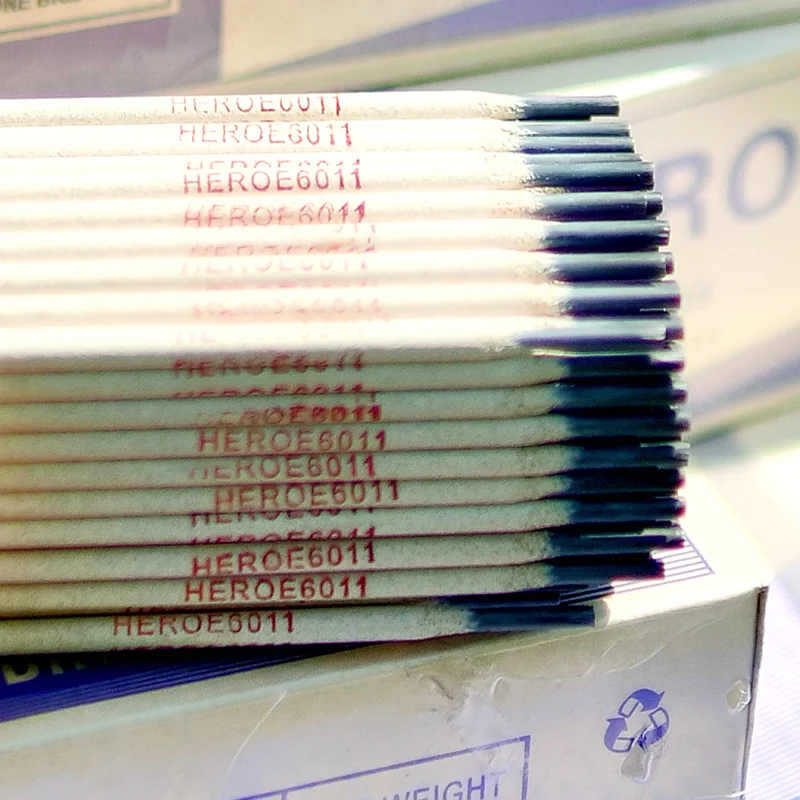

Ever stared blankly at a welding rod, wondering what all those letters and numbers mean? You're not alone. It's like code. But who cracks this code? Who decides that E7018 is different from E6010? Let's dive in!

The All-Knowing Wizard: AWS

Prepare yourselves. The answer, drumroll please... it's the American Welding Society (AWS). Yes, a whole society! I picture them in robes, chanting about tensile strength. Okay, maybe not. But they *do* set the standard.

Think of AWS like the grammar police, but for welders. They create the rules. They decide what's acceptable. And they write the specs. This ensures welders aren't just randomly sticking metal together hoping for the best.

Essentially, the AWS defines the classification system. They publish documents, standards, and guidelines. These are the rulebooks. If a welding rod wants to be called E7018, it has to meet *their* criteria.

But... It's Not *Just* AWS

Okay, here's where my unpopular opinion comes in. Yes, the AWS is the official rule-maker. But...they don't work in a vacuum. Rod manufacturers play a big part too. They design, test, and then *apply* to have their rods classified.

The AWS sets the bar, but the manufacturers have to clear it. They have labs. They run tests. They prove their rods can do what they say they can do. It's like applying for a job, but the job is "welding things together really, really well."

And let's be honest, user feedback is probably a factor too. Welders in the field are using these rods. They're giving feedback, good and bad. Word gets around about which rods perform and which ones... don't.

The Secret Ingredient: Collaboration

So, is it *just* AWS? Technically, yes. They assign the classifications. But practically? It's a team effort. Manufacturers, welders, and even researchers contribute to the process. It's a whole ecosystem of welding knowledge!

It's like saying a chef creates a dish. Sure, they put the ingredients together. But the farmers grew the ingredients. The suppliers delivered them. The testers taste-tested it. It's a collaborative culinary creation!

So next time you see those letters and numbers, remember it's not just some random code. It's the result of standards, testing, and a whole lot of metal-melting know-how. And maybe a little bit of magic too. Shhh! Don't tell anyone I said that.

Unpopular Opinion Time!

Here it is: I think the AWS should take user reviews more seriously. Imagine a welding rod rating system, like Amazon reviews for electrodes. "This E6010 sputters like a grumpy cat – 2 stars." "This E7018 is smooth as butter – 5 stars, would weld again!"

Okay, maybe not *exactly* like that. But incorporating real-world welder experience could make the system even better. It's one thing to meet lab standards. It's another to perform flawlessly in a real-world environment.

Just a thought. Don't @ me, AWS. I still respect your robe-wearing (probably imaginary) authority.

Ultimately, the classification of carbon steel covered electrodes boils down to a complex interplay.

The AWS sets the standards, but manufacturers meet them, and welders rely on them.It's a system built on precision, reliability, and the occasional spark of ingenuity.

So, the answer? It’s assigned by the AWS, but influenced by *everyone* involved in the world of welding.