Alright folks, let's talk exhaust pipes. You know, those rusty serpents that snake their way under your car, belching out the byproducts of internal combustion. They're like the automotive equivalent of your digestive system – crucial, but rarely glamorous. And like our own guts, they occasionally spring a leak. That's where we, the weekend warrior welders, come in.

So, your exhaust pipe's decided to imitate a rusty bagpipe, huh? Making noises that scare the neighborhood cats? Don't despair! You *can* fix it. The key ingredient (besides a healthy dose of patience and maybe a cold beverage) is the right welding rod.

Why the Right Rod Matters (Like Matching Socks)

Imagine trying to glue two Lego bricks together with chewing gum. Sure, you might get them to *stick* for a minute, but it's not exactly a permanent solution. Using the wrong welding rod on your exhaust pipe is kind of like that. It might look okay at first, but that vibration, heat, and general abuse will laugh at your pathetic attempt and crack the weld faster than you can say "warranty voided."

The goal? A weld that's stronger than a toddler's grip on a cookie. And to get there, we need to understand what we're welding. Exhaust pipes are usually made of either mild steel or aluminized steel. *Knowing which you're dealing with is half the battle!*

Mild Steel Mayhem: The Easiest Route

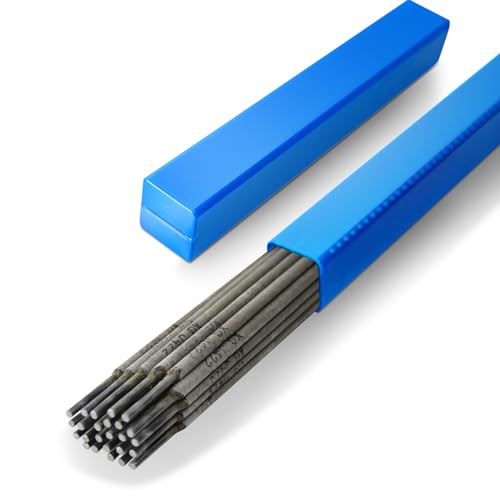

Mild steel is the friendliest of the bunch. It's like that neighbor who always offers you a beer and asks how your lawnmower is doing. For mild steel exhaust pipes, **E6013 or E7014 welding rods are your go-to choices**. Think of them as the duct tape of the welding world – versatile, reliable, and readily available at pretty much any hardware store.

E6013 is known for its smooth arc and easy slag removal (that crusty stuff you chip off after welding). It's forgiving, meaning even if your welding skills are still a bit… *rustic*, you can usually get a decent weld with this rod.

E7014 is similar to E6013 but generally offers slightly better penetration. Translation: it melts deeper into the metal, creating a stronger bond. It's like using extra glue on that Lego project – you're just adding a bit of insurance.

Aluminized Steel Adventures: A Bit More Fussy

Aluminized steel is where things get a tad more complicated. This stuff has a thin coating of aluminum to help prevent rust, which is great for longevity but not so great for welding. It's like trying to paint a slippery surface – the paint just doesn't want to stick. So, what rod should we use?

Here's the kicker: For aluminized steel, MIG welding with the correct wire and gas is generally the *best* approach. However, if you're sticking (pun intended) with stick welding, you *can* use nickel-based rods like ENi-Cl. These rods are designed to weld cast iron, and they can also work on aluminized steel, *but they require a bit more finesse*.

Nickel rods are like that fancy imported cheese you're not quite sure how to eat – they're expensive and a little temperamental. You'll need to clean the metal extremely well, preheat the area slightly, and use a lower amperage. And even then, the weld might not be as strong as a MIG weld. Basically, use this option if you're feeling adventurous and don't mind potentially redoing the weld later.

Prep Work: Your Secret Weapon

No matter which rod you choose, *prep work is key!* Think of it as giving your exhaust pipe a spa day before the welding begins. Clean the area thoroughly with a wire brush or grinder to remove rust, dirt, and any other contaminants. This ensures the weld has a clean surface to adhere to.

A clean exhaust pipe is a happy exhaust pipe (and a happy welder!). And trust me, a happy welder is less likely to throw their helmet across the garage in frustration. We've all been there, right?

Final Thoughts: Practice Makes (Almost) Perfect

Welding is a skill that takes practice. Don't expect to become a master welder overnight. Start with some scrap metal and experiment with different rods and settings until you find what works best for you. And remember, safety first! Always wear a welding helmet, gloves, and proper clothing to protect yourself from sparks and UV radiation.

So, there you have it. A (hopefully) helpful guide to choosing the best welding rod for your exhaust pipe. Now go forth and conquer those rusty bagpipes! And if all else fails, there's always duct tape… just kidding (mostly).