So, you're thinking about wrestling with stainless steel? Cutting a hole in that stuff can feel like trying to slice through a bank vault with a butter knife. Seriously! But fear not, intrepid DIYer! There's a secret weapon. It's called a hole saw, and it’s your ticket to conquering that shiny, tough material.

Now, not just any hole saw will do. You can't just grab the dusty one from the back of your grandpa's garage (unless your grandpa was a metalworking wizard, of course). Stainless steel demands respect, and that respect comes in the form of the right tool. Think of it like this: you wouldn't bring a slingshot to a laser tag battle, would you?

The Stainless Steel Slayer: Bi-Metal Hole Saws

Enter the bi-metal hole saw. What’s “bi-metal,” you ask? Simply put, it's a hole saw built with two different types of metal. Usually, you'll find tough, high-speed steel (HSS) teeth welded to a more flexible body. This combination is key. The HSS teeth are hard enough to bite into stainless steel, while the flexible body prevents the whole thing from shattering under pressure. Pretty clever, right?

Imagine the teeth of the saw as tiny, tireless ninjas, silently and efficiently chipping away at the stainless steel. Okay, maybe not *silently*, but definitely efficiently if you use the right technique! More on that later.

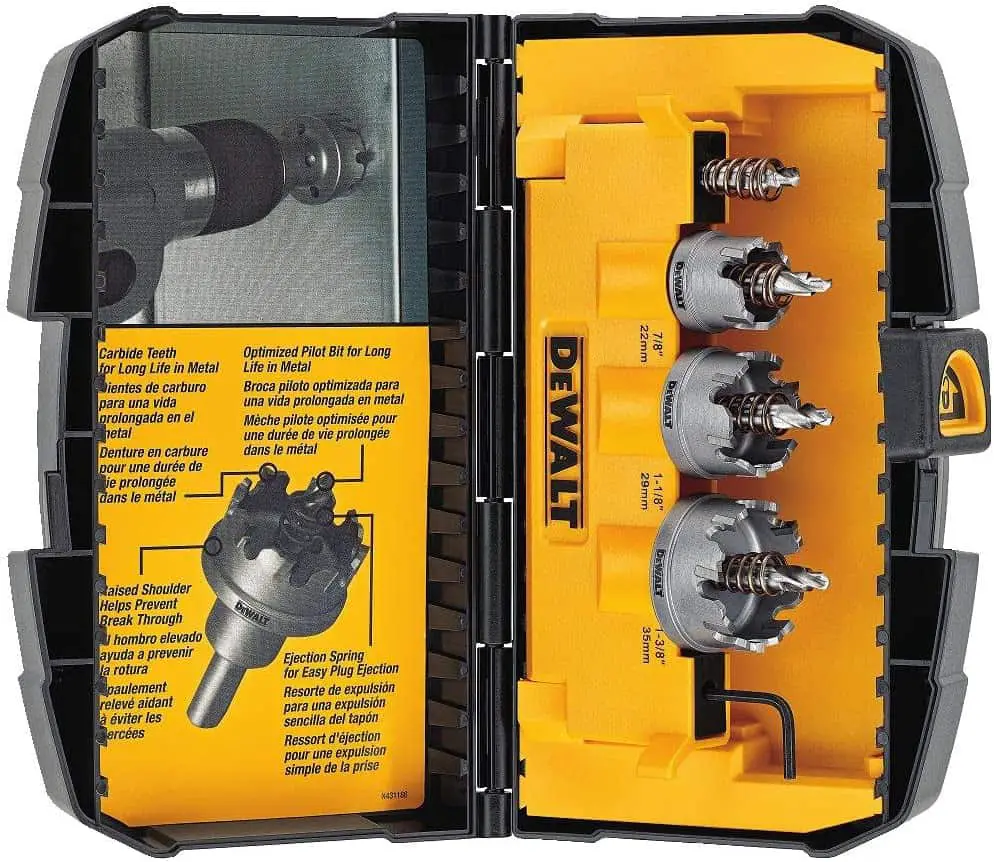

Carbide Tipped: The Heavy Artillery

If you're dealing with some seriously thick stainless steel, or perhaps a particularly stubborn alloy, you might need to call in the heavy artillery: the carbide-tipped hole saw. These bad boys have teeth made of carbide, which is even harder and more heat-resistant than HSS. They're like the superheroes of hole saws, ready to tackle any challenge.

Think of a carbide-tipped hole saw as the equivalent of a diamond-edged sword for metal. These are more expensive, sure, but they'll laugh in the face of the toughest stainless steel projects. And let’s be honest, who doesn't want a tool that laughs at difficult tasks?

The Importance of Pilot Holes and Cutting Fluid

Okay, you've got your hole saw. You're ready to rock. But hold your horses! There are a couple of crucial steps you absolutely cannot skip. First, the pilot hole. Use a center punch to create a small indentation where you want the center of your hole to be. Then, drill a pilot hole using a drill bit. This gives the pilot drill of your hole saw something to grab onto, preventing it from wandering all over the place like a lost puppy.

Second, and this is super important, use cutting fluid. This isn't just some fancy extra. Cutting fluid acts as a lubricant and coolant, reducing friction and heat. Stainless steel gets hot very quickly when you're cutting it, and that heat can dull your hole saw, or even worse, warp the metal. Cutting fluid keeps things cool and prevents that from happening. It's like giving your hole saw a refreshing drink after a hard workout.

Think of cutting fluid as the best friend of your hole saw and the key to a smooth, clean cut. Don't leave home without it!

Technique Matters: Slow and Steady Wins the Race

When cutting stainless steel, patience is a virtue. Don't try to force the hole saw through the metal. Apply gentle, consistent pressure and let the saw do the work. Use a slow speed on your drill. High speeds generate more heat, which, as we've already established, is the enemy. Think of it like meditation for your power tools. Slow, deliberate, and focused.

Clear the chips frequently. As you cut, metal shavings will accumulate in the hole. Stop periodically and remove these chips. This prevents them from clogging the saw and generating even more heat. It’s like giving your hole saw a chance to breathe.

Safety First!

Before you even think about touching that drill, put on your safety glasses! Flying metal chips are no joke. Also, wear gloves to protect your hands from sharp edges and heat. And for goodness sake, unplug the drill before changing hole saws! It's common sense, but it bears repeating.

The Joy of the Perfect Hole

There's something deeply satisfying about cutting a perfect hole in stainless steel. It's like conquering a tiny mountain. You started with a seemingly impenetrable material, and with the right tool, the right technique, and a little bit of patience, you emerged victorious, wielding a flawlessly round hole. It’s a feeling that’s hard to beat!

So, go forth and conquer! Arm yourself with the right hole saw, embrace the power of cutting fluid, and remember to take it slow. You'll be amazed at what you can achieve. Happy drilling!