Alright, let's talk bend radius. You know, that curved bit when you bend sheet metal? Yeah, that's the one. Sounds simple, right? Ha! But get it wrong, and you're looking at cracked metal, distorted shapes, and a whole lot of frustration. And nobody wants that, do they?

So, what's the secret weapon against bending bloopers? The bend radius chart! Basically, it's your cheat sheet for knowing what radius works best for your specific material and thickness. Think of it as a roadmap, guiding you away from metal-bending mayhem. Dramatic, I know, but seriously, it can save your project!

Why Bother With a Bend Radius Chart?

Good question! Why *should* you bother? Well, imagine trying to fold a piece of paper too sharply. What happens? It creases, right? Sheet metal does the same thing, only instead of a little paper crease, you get a big, ugly crack. Not ideal.

A bend radius that's too small – we’re talking way too small – can lead to all sorts of problems. Cracking, as we mentioned, is a big one. But also: increased stress on the metal, weakening the whole structure. And let's not forget the possibility of springback (when the metal tries to return to its original shape after bending). Annoying, isn't it?

On the flip side, a bend radius that's too large…well, it might not cause structural damage, but it can mess with your design. Suddenly, your perfectly planned box is looking all…roundish. Not the aesthetic you were going for, I bet.

So, the bend radius chart helps you find that sweet spot. The Goldilocks zone of bending. Not too hard, not too soft, just right!

Decoding the Chart: It’s Not Rocket Science (Promise!)

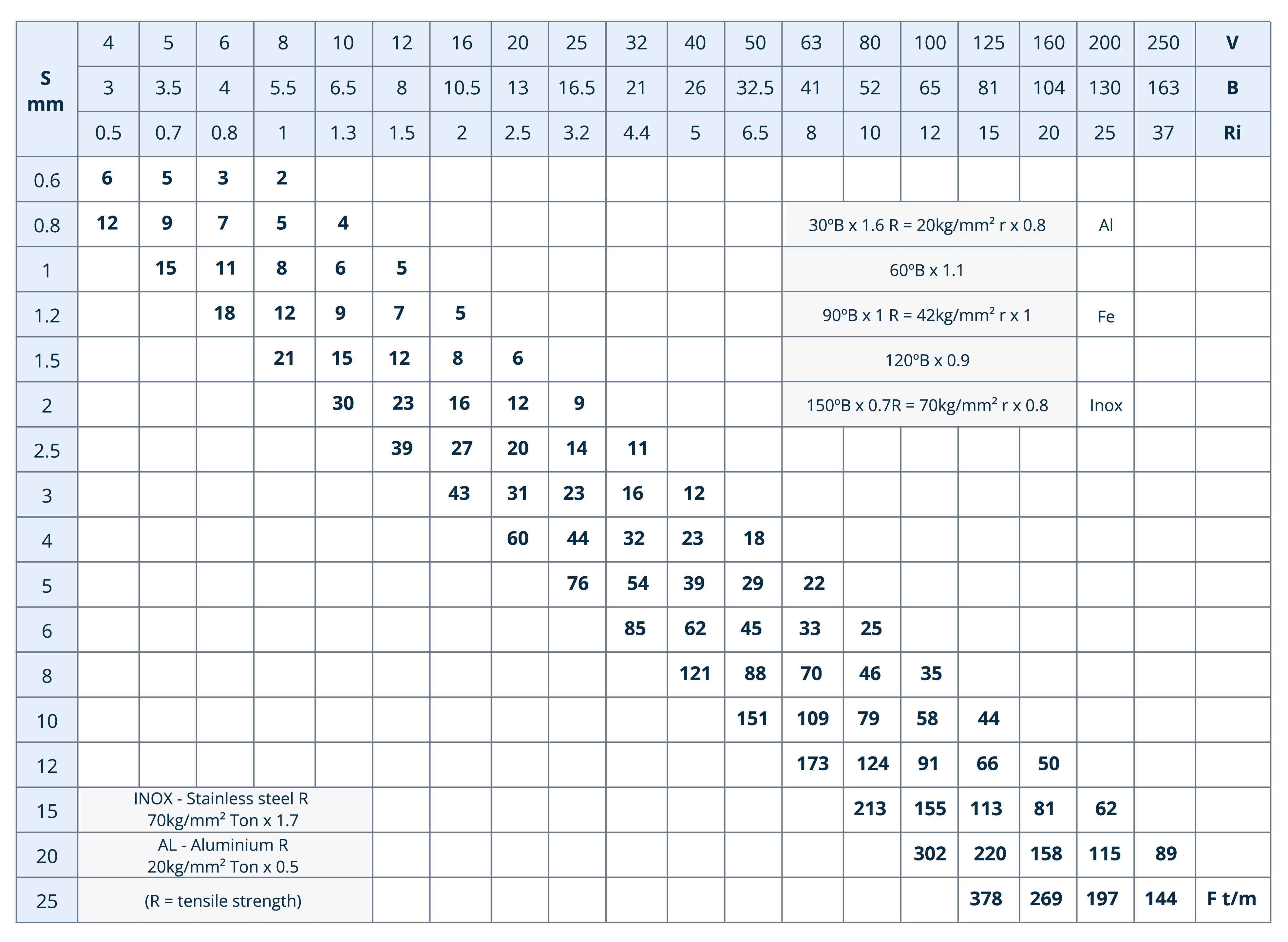

Okay, so you've got a bend radius chart staring back at you. Don't panic! They might look intimidating at first, but they're actually pretty straightforward. Think of it as a really helpful table.

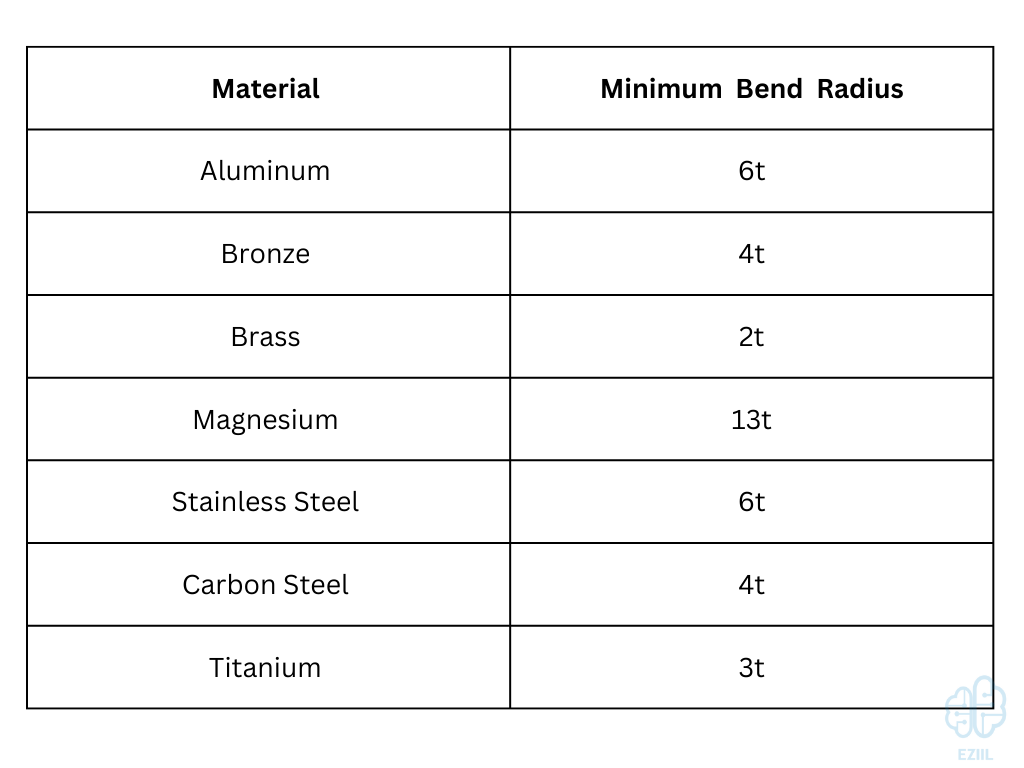

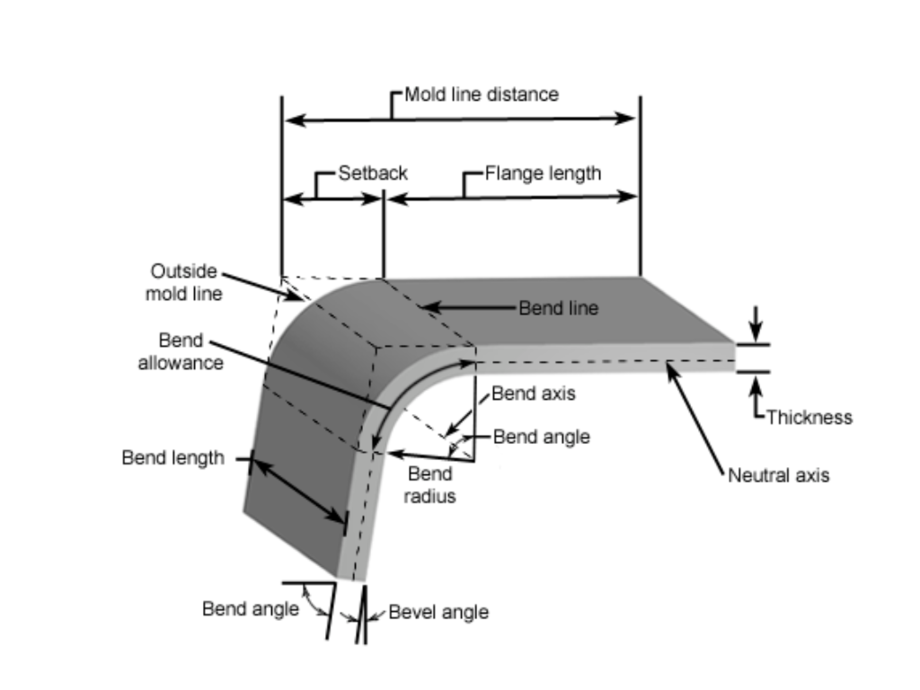

Typically, the chart will list different materials (like steel, aluminum, stainless steel), along with various thicknesses. Then, corresponding to each material and thickness, you'll find a recommended bend radius. Ta-da!

For example, the chart might tell you that for 16-gauge steel, a bend radius of 0.062 inches is ideal. See? Not so scary, is it?

Important Note: Always double-check which units the chart is using (inches, millimeters, etc.). Getting that wrong is a recipe for disaster!

Factors That Influence the Bend Radius (Besides the Chart)

Okay, the chart is a great starting point, but it's not the *only* thing to consider. There are a few other factors that can affect your ideal bend radius. We’re talking about things like:

- The Bending Method: Are you using a press brake? A folder? A roller? Each method can influence the outcome.

- The Grain Direction: Yep, even the direction the metal was rolled can make a difference. Bending *across* the grain is generally tougher than bending *with* it. Who knew, right?

- Temperature: Bending metal when it's cold can make it more brittle. Consider warming it up a bit, especially with certain materials. Think of it like stretching before a workout – it prevents injuries!

Finding the Right Chart (Because They're Not All Created Equal)

So where do you get your hands on a bend radius chart? The good news is, they're pretty easy to find online. A quick search for "bend radius chart sheet metal" should turn up plenty of options.

Pro Tip: Try to find a chart that's specific to the type of metal you're working with. A general-purpose chart is better than nothing, but a material-specific one will give you more accurate results.

Also, don't be afraid to consult with the metal supplier or manufacturer. They often have their own recommended bend radii based on their specific materials and processes. Think of them as bending gurus!

Final Thoughts: Bend It Like a Pro!

So there you have it: a crash course in bend radius charts. Remember, taking the time to consult the chart (and consider those other factors we talked about) can save you a ton of headaches (and wasted materials) in the long run.

Happy bending!