Okay, let's talk about something seriously cool: Argon welding for stainless steel. I know, I know, "welding" might conjure up images of dusty garages and sparks flying everywhere. But trust me on this, it's way more fascinating (and frankly, useful!) than you might think. Especially when we're talking about stainless steel and the magic of argon.

Why argon, you ask? Good question! Imagine stainless steel as a delicate flower. Beautiful, strong in its own way, but easily bruised by the harsh realities of, say, oxygen. When you weld, things get HOT. Regular welding in the open air exposes the molten metal to oxygen, leading to oxidation, which basically means rust, discoloration, and a weakened weld. Bummer, right?

That's where our hero, argon gas, swoops in! Argon is an inert gas, meaning it doesn't react with... well, anything much. It's like a bodyguard for your stainless steel, shielding it from the nasty effects of the atmosphere. Think of it as a fancy, invisible, force field. Cool, huh?

So, Why Stainless Steel Anyway?

Hold on, before we get too far ahead, why are we even bothering with stainless steel in the first place? Simple: It's awesome! Stainless steel is strong, corrosion-resistant, and looks fantastic. We see it everywhere: in kitchens (sinks, appliances, cookware), architecture (those sleek, modern buildings), and even medical equipment (because it's super hygienic).

And because stainless steel is so versatile, knowing how to weld it opens up a whole world of possibilities! Fancy building your own custom kitchen island? Check. Repairing that awesome stainless steel exhaust system on your car? Check. Creating a stunning piece of metal art? Double-check! (Okay, maybe triple-check – that last one takes practice!).

The Magic of TIG Welding

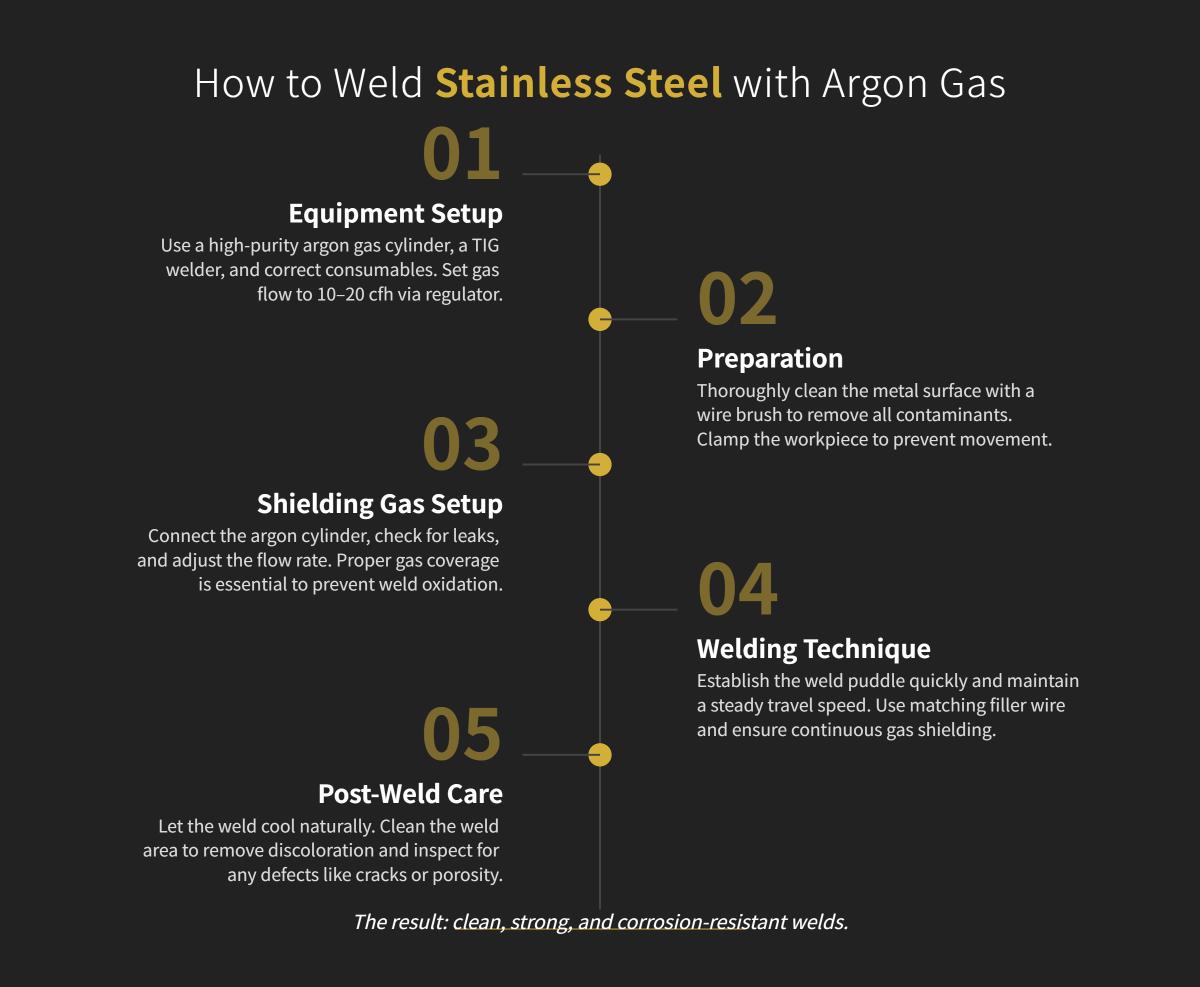

Now, to get the best results with stainless steel and argon, we usually use a process called TIG welding, which stands for Tungsten Inert Gas welding. (Sometimes also referred to as GTAW – Gas Tungsten Arc Welding). Don't let the jargon intimidate you. The basic idea is that a non-consumable tungsten electrode creates an arc of electricity, melting the stainless steel. And, you guessed it, argon gas flows around the weld, protecting it from contamination.

TIG welding gives you incredible control. You can precisely control the heat and the amount of filler metal (if you're using any), which leads to clean, strong, and beautiful welds. Think of it as the “fine art” of welding. It might take a bit of practice to master, but the results are worth it. (And hey, practice makes perfect, right?).

Here's a quick visual: Imagine holding a pen (the TIG torch) and "drawing" a bead of molten stainless steel, all while a shield of argon protects your masterpiece. Pretty cool, huh?

Why Should *You* Learn This?

Alright, let's get down to brass tacks. Why should you, sitting there reading this article, even consider learning argon welding for stainless steel?

- DIY Projects: Think of all the amazing projects you could tackle! From custom furniture to automotive repairs, the possibilities are endless.

- Career Opportunities: Skilled welders are in high demand! Knowing TIG welding, especially for stainless steel, can open doors to a lucrative and fulfilling career.

- Creative Expression: Welding isn't just about joining metal; it's about creating! You can use your skills to make stunning sculptures, unique pieces of art, and express your creativity in a whole new way.

- Pure Satisfaction: There's something incredibly satisfying about taking raw materials and transforming them into something beautiful and functional with your own two hands. Trust me, the feeling is addictive!

Getting Started – It's Easier Than You Think!

So, where do you begin? Don't worry, you don't need to buy a million-dollar welding rig to get started. There are plenty of affordable TIG welders on the market, and you can often find used equipment at a good price.

The best way to learn is to take a class or workshop. Many community colleges and technical schools offer welding courses, and there are even online resources available. Don't be afraid to ask questions, practice consistently, and learn from your mistakes. (We all make them!).

Pro tip: Start with simple projects and gradually work your way up to more complex ones. Practice on scrap metal until you feel comfortable with the process.

Trust me, learning to argon weld stainless steel is an investment in yourself. It's a skill that can open doors to new opportunities, unleash your creativity, and give you a deep sense of accomplishment. And who knows, you might just discover a hidden talent that you never knew you had!

So go ahead, take the plunge! Explore the world of argon welding for stainless steel. You might be surprised at how much fun you have and how much you can achieve. The world is waiting for your next metal masterpiece! Now, go forth and weld with confidence!