Alright, let's talk aluminum TIG welding filler rods. Sounds technical, doesn’t it? Like something only rocket scientists and race car mechanics need to worry about. But trust me, even if the closest you get to welding is watching someone else do it on TV, understanding these little guys can be surprisingly useful. Think of it like knowing what kind of flour goes into your favorite cake – you don't need to bake it yourself to appreciate the difference!

Why Should You Even Care?

Okay, fair question. Why *should* you care? Well, think about all the aluminum stuff in your life. From the shiny trim on your car to the sturdy frame of your bicycle, from the sleek casing of your laptop to the garden furniture that stubbornly refuses to rust, aluminum is everywhere. And chances are, somewhere along the line, welding – specifically TIG welding – was involved in putting those things together.

TIG (Tungsten Inert Gas) welding is like the surgical precision of welding. It's clean, it's controlled, and it's often used for joining aluminum because, well, aluminum can be a bit of a diva to weld. And that's where the filler rod comes in. It's the magic ingredient, the *glue* that binds those aluminum pieces together, creating a strong and beautiful weld.

Imagine you’re building a model airplane. The glue you use makes all the difference, right? Cheap, watery glue will lead to a flimsy plane that falls apart at the first breeze. Good, strong glue, perfectly suited to the materials, creates a sturdy, flyable masterpiece. Aluminum TIG filler rods are the "good glue" for aluminum welding.

Decoding the Mystery: Common Types

Now, let's not get bogged down in super technical jargon, but knowing a couple of the most common types of aluminum TIG filler rods can be helpful. Think of it like knowing the difference between a Granny Smith and a Honeycrisp apple – both are apples, but they have distinct characteristics.

4043: This is probably the workhorse of aluminum filler rods. It's like the reliable family sedan – it gets the job done. It flows well, it's relatively forgiving, and it's great for general-purpose welding. You'll often find it used on cast aluminum parts, like engine blocks. *Think of it as the "easy-bake oven" version of aluminum welding.* It’s not always the prettiest, but it gets the job done reliably.

5356: This rod boasts higher strength and better corrosion resistance. It’s like the sporty convertible of the aluminum world – stylish and capable. It's used in applications where strength is critical, like structural components and marine applications. It also gives a slightly brighter, more aesthetically pleasing weld. It's your go-to for projects where strength *and* looks matter.

Other Flavors: There are other types too, each with their own specific properties and uses. But for everyday purposes, 4043 and 5356 are the ones you'll most likely encounter. It’s like knowing the difference between a regular screwdriver and a Phillips head – for most household tasks, those two will cover 90% of your needs!

Why the Right Rod Matters

Choosing the right filler rod isn't just about making a weld; it's about making a *good* weld. A weld that’s strong, durable, and resistant to corrosion. A weld that won't crack or fail under stress.

Imagine trying to repair a cracked aluminum boat hull with the wrong kind of filler rod. You might get a temporary fix, but sooner or later, that weld is going to fail, and you'll be back in the water (literally!). Using the correct rod, on the other hand, will create a strong, watertight repair that will last for years.

It's like using the right kind of oil in your car engine. Use the wrong oil, and you'll risk damaging your engine, leading to costly repairs. Use the correct oil, and your engine will run smoothly and efficiently for years to come.

Don’t be penny-wise and pound-foolish. Spending a few extra bucks on the right filler rod can save you a lot of headaches down the road.

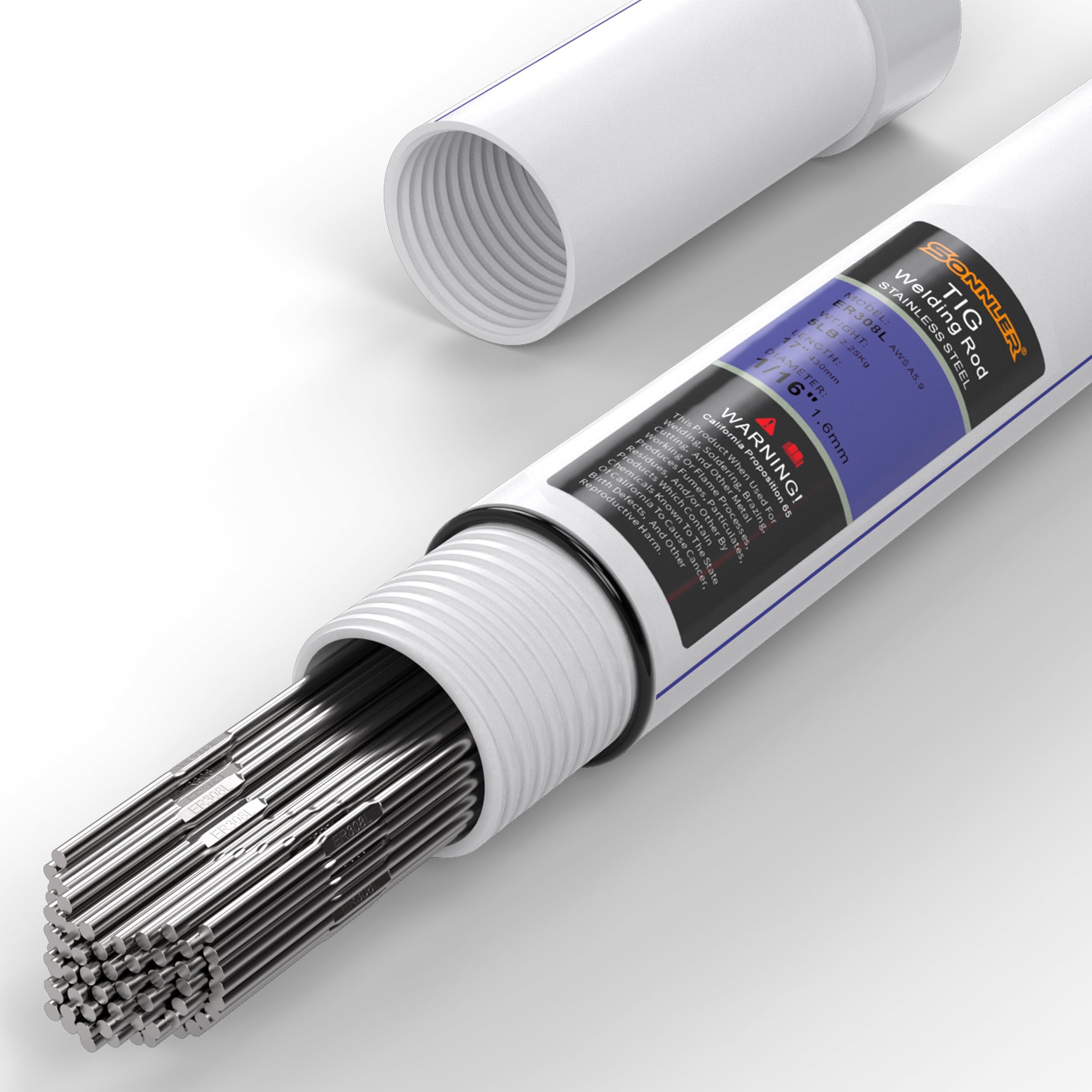

Beyond the Basics: Size and Storage

Filler rods come in different sizes, typically measured in diameter. Choosing the right size depends on the thickness of the aluminum you're welding and the amperage you're using. Too small, and you'll struggle to build up the weld. Too big, and you'll end up with a messy, uncontrollable blob.

And finally, a quick word about storage. Aluminum filler rods are susceptible to corrosion, so it's important to store them in a dry, airtight container. Think of it like storing potato chips – leave them open to the air, and they'll go stale and soggy. Keep them sealed in a bag, and they'll stay crispy and delicious for days (if they last that long!). Properly stored filler rods will give you cleaner, stronger welds.

So, there you have it! A (hopefully) painless introduction to the world of aluminum TIG welding filler rods. You might not be rushing out to buy a welding machine tomorrow, but hopefully, you now have a better appreciation for the "glue" that holds so much of our modern world together.